Waste? No, it is an eco-friendly solution for road construction

In order to reduce the amount of bitumen production waste as much as possible, plant Mida LT (part of TECHNONICOL in Lithuania) found a way to return it into the circular economy cycle. This important step for the country’s ecology would not have been successful without close cooperation with scientists from Vilnius Gediminas Technical University (VGTU).

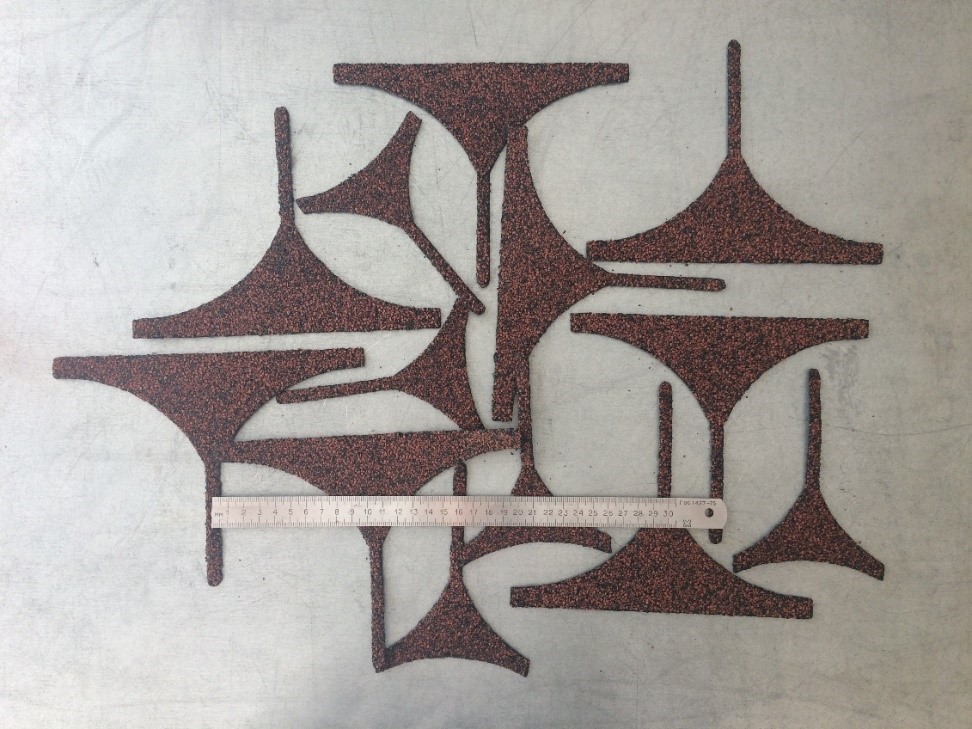

The plant for the production of bituminous membranes and roofing shingles generates several hundred tons of bituminous waste and scrap per year, which presents significant potential for recycling. Instead of simply taking it to a landfill, a much greener solution can be made and such bituminous waste and scrap can be recycled. This practice is used in the United States, where similar production waste and scrap are used in road construction.

|

|

Researchers at VGTU confirmed that the waste and scrap generated during the production are suitable for use in road construction. It can be dual use. In particular, the scrap can replace sand or gravel on inland roads (of medium and light loads) – in forests, national parks, state protected areas, borders, quarries or courtyard roads. The second way to use this waste is to shred it into pieces of up to 10 mm in size. Such particles can replace part (approximately 5-7 %) of the bitumen used in the production of asphalt concrete mixtures. Road construction solutions based on replacement of a portion of the bitumen with particles can be applied to the construction of roads of state importance.

The results of this study open up wide possibilities for the secondary use of scrap left over from the production of bituminous coatings. In roads constructed using asphalt with particles of bituminous coatings, the pavement will be slightly stiffer and more resistant to rutting than usual, due to the fibres and polymers contained in the shredded bituminous pavement particles. In addition, since bitumen is the most expensive composite material of the asphalt mixture, replacing part of it with shredded bituminous pavement particles should make road construction a little cheaper.

To be put into practice as early as this year

Based on the results of the study, researchers at VGTU prepared recommendations for the internal production control system. After their installation, the bituminous waste and scrap generated in the production of bituminous roof and facade coatings will be successfully certified for use in the construction of internal roads and in the production of asphalt mixtures.

“Of course, the state of emergency declared in Lithuania due to the Covid-19 coronavirus epidemic will slow down our actions a bit, – says Andrius Jakas, CEO of MIDA LT, – but will not stop it. We are finalizing the regulatory documentation for the use of whole pieces on roads of local significance. The shredding equipment is already prepared.”

The head of the company says that in the next six months, despite all the problems caused to the business and production caused by the epidemic, the plant will start supplying bituminous roof and facade scrap and particles to road construction companies.